Salt Spray Test Astm B117 Pdf

Salt spray test astm b117 pdf. Salt Spray Fog Testing to ASTM B117-18 Figure 6. ASTM B117 Testing Operating Salt Spray Fog Apparatus Study Date. X-pipe X-pipe S2S-pipe a After 336 hrs b After 500 hrs S2S -pipe.

Evidence of corrosion on X-pipes after a 336 and b 500 hours of salt spray testing. Corrosion resistance in a controlled corrosive environment in accordance with ASTM B-117- 09 Standard Practice for Operating Salt Spray Fog Apparatus. Modification of ASTM B117 Salt Spray Corrosion Test and Its Correlation to Field Measurements of Silver Corrosion March 2012 Corrosion -Houston Tx- 683036001-1-036001-10.

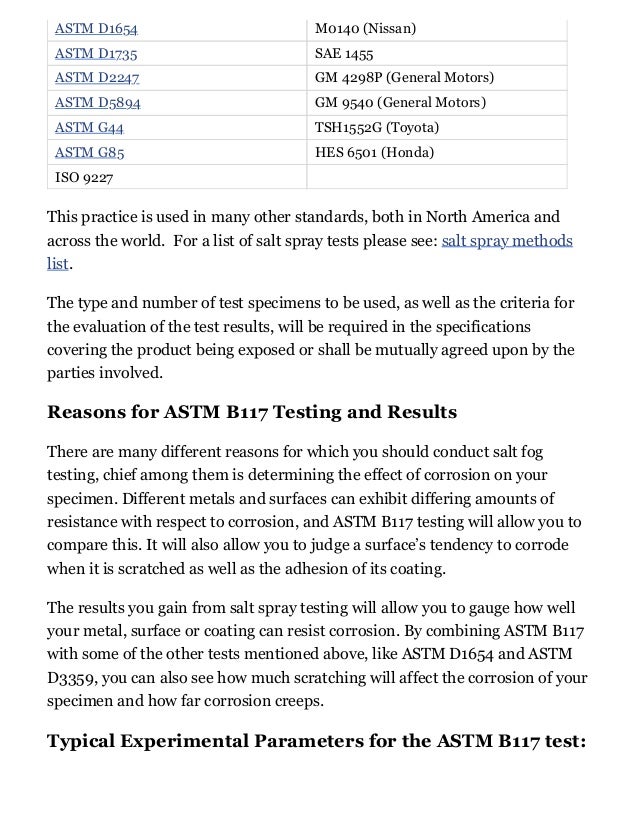

Non-Chrome seal rinse with reverse osmosis water with 30 -45 second dwell times. 12 This method is based on ASTM B117 edition 2011 which consists of. ASTM B 117 97 Standard Practice for Operating Salt Spray Fog Apparatus Keywords.

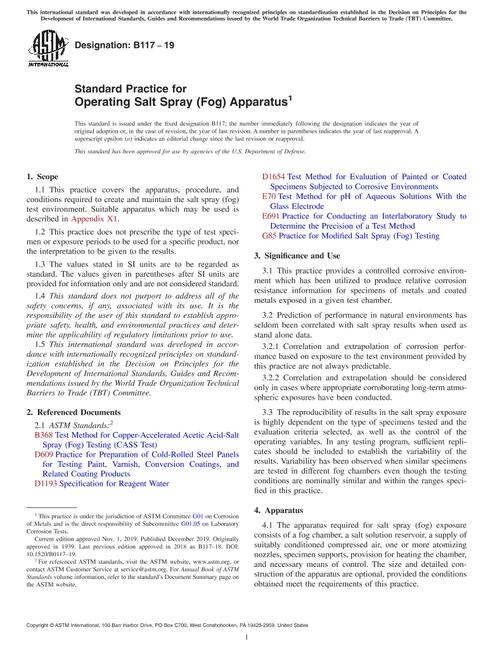

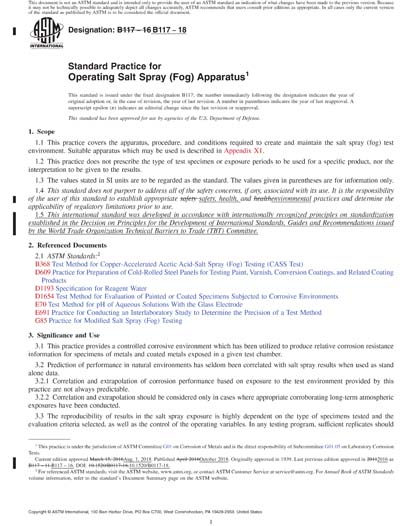

The ASTM B 117-95 testing procedure is the HVAC industry standard method of testing the acceptability and longevity of a paint finish. 12388 88th Ave Surrey BC. D609 Practice for Preparation of Cold-Rolled Steel Panels for Testing Paint Varnish Conversion Coatings and Related Coating.

Iron Carbon 12 Chromium 105 Stainless Steel. SALT SPRAY TESTING PER ASTM B---117. ASTM B 117 97 Standard Practice for Operating Salt Spray Fog Apparatus Created Date.

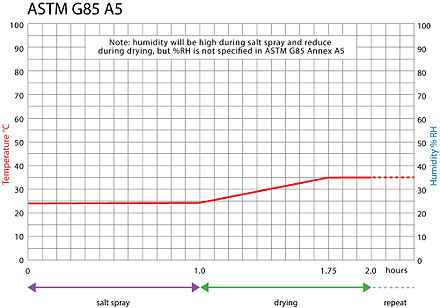

The classical salt spray fog test ASTM B117 consists of atomizing a salt solution into uniform droplets on specimens supported or suspended between 15-30 from the vertical. Preliminary exercise to compare the performance of some PM stainless steels materials tested in accordance with ASTM B895 immersion in 5 NaCl and ASTM B117 salt spray testing3-4 This initial work will be used to define the procedure for evaluating additional PM stainless steel materials. 362019 110949 AM.

Our lab is A2LA accredited to perform ASTM B117 salt spray testing. The number immediately following the designation indicates the year of original adoption or in the case of revision the year of last revision.

The number immediately following the designation indicates the year of original adoption or in the case of revision the year of last revision.

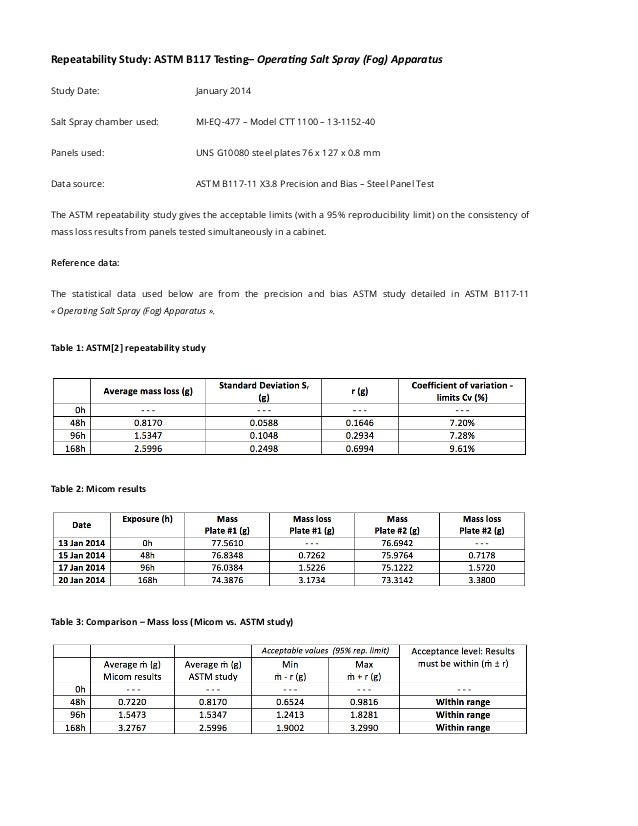

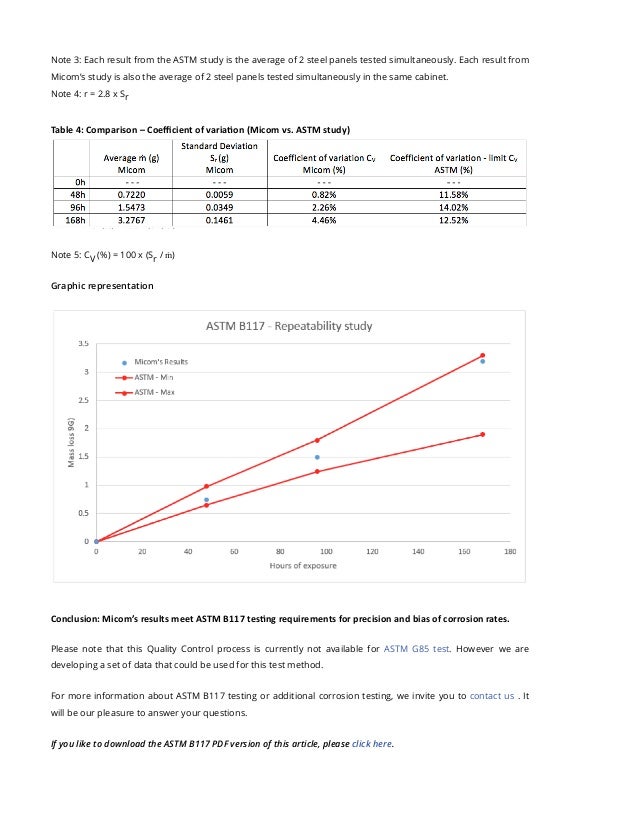

UNS G10080 steel plates 76 x 127 x 08 mm Data source. 13 The chamber will be loaded with test samples as required by the customer. This report should serve as a general guide and IFS COATINGS assumes no obligation or liability for use of this information. Evidence of corrosion on X-pipes after a 336 and b 500 hours of salt spray testing. MATERIALS SOLUTIONS TEST REPORT Powertech Labs Inc. 4 The salt solution is a solution of 5 in weight of NaCl more than sea water. For the test panels are placed in a 5salt spray and fog atmosphere for measured periods of time. ASTM B 117 97 Standard Practice for Operating Salt Spray Fog Apparatus Keywords. This report is for the exclusive use of the customer to whom it is addressed.

ASTM B117 Salt Spray and Salt Fog Testing ASTM B117 is an American standard that provides a controlled accelerated corrosive environment to evaluate the coatings or substrates corrosive resistance. Salt Spray Test Report Per ASTM B117 At 1000 hours. 4 The salt solution is a solution of 5 in weight of NaCl more than sea water. ASTM B117-11 X38 Precision and Bias - Steel Panel Test. The classical salt spray fog test ASTM B117 consists of atomizing a salt solution into uniform droplets on specimens supported or suspended between 15-30 from the vertical. 362019 110949 AM. Non-Chrome seal rinse with reverse osmosis water with 30 -45 second dwell times.

Posting Komentar untuk "Salt Spray Test Astm B117 Pdf"